Shipping chemicals by air vs. sea: a comprehensive guide to modes, costs, and regulations

The chemical logistics landscape is recently defined by volatility. With fluctuating freight rates and shifting geopolitical realities, Logistics managers are constantly balancing the “Need for Speed” against “Budget Constraints.” While sea freight traditionally handles the bulk of global trade volume, air freight remains an indispensable strategic tool for high-value, time-sensitive shipments.

This comprehensive guide dissects the critical trade-offs between Air and Sea transport, providing a decision matrix based on regulations, operational realities, and financial impact.

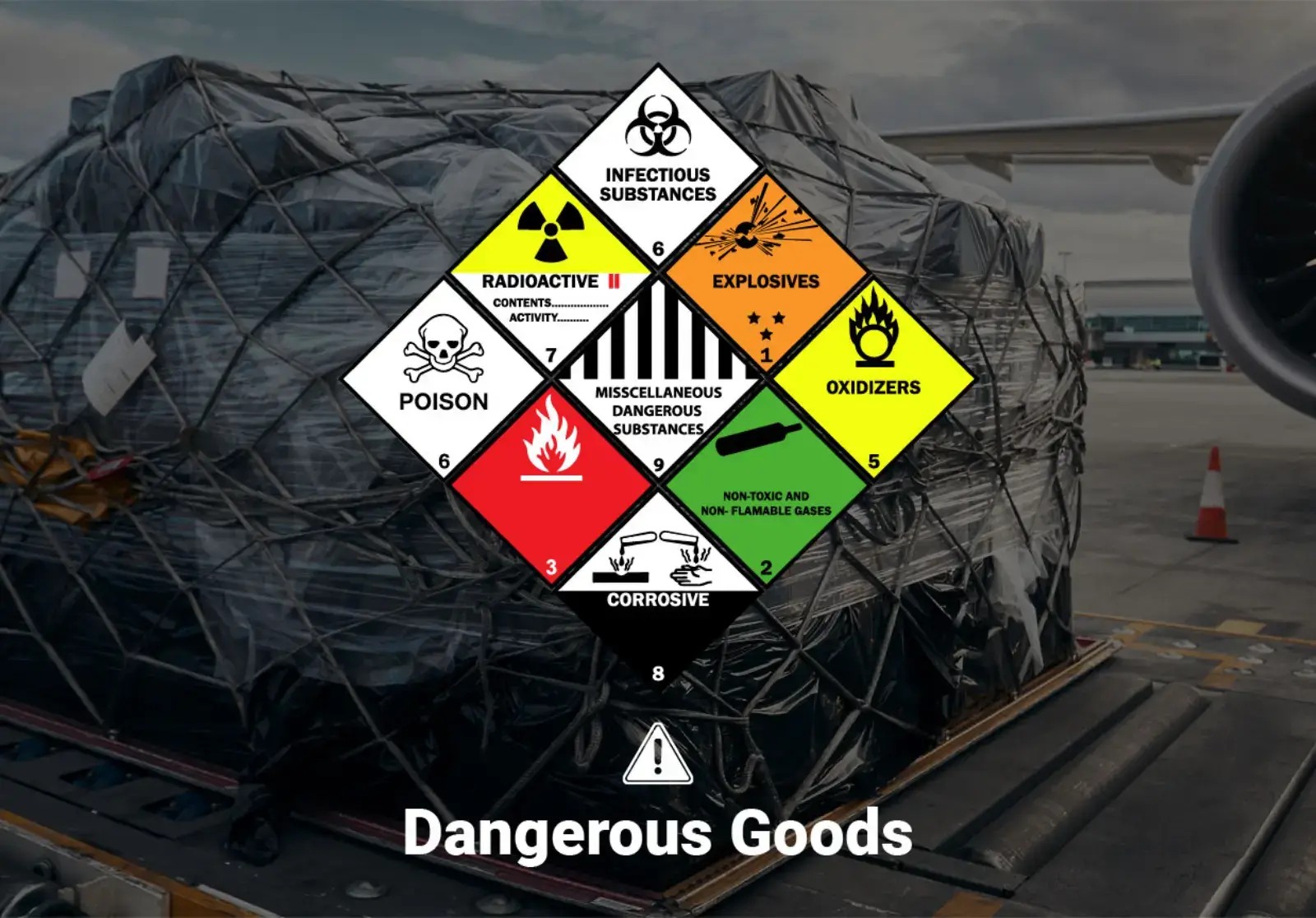

The Regulatory Landscape: Compliance as the Foundation

In chemical logistics, safety is not just a priority; it is a rigid legal requirement. The choice of mode dictates which regulatory framework applies, significantly influencing packaging and documentation.

Air Freight: The IATA Dangerous Goods Regulations (DGR)

Air transport is governed by the strictest safety standards. The IATA Dangerous Goods Regulations (DGR) sets the global standard for shipping hazardous materials by air.

- Strict Quantity Limits: Unlike sea freight, air cargo has stringent “Net Quantity per package” limitations.

- Shipper’s Responsibility: The shipper is legally responsible for identifying, classifying, packing, marking, labelling, and documenting the shipment. A key document is the Shipper’s Declaration for Dangerous Goods, which must be accurate to the letter to avoid rejection.

- “Cargo Aircraft Only” (CAO): Certain chemicals that are too hazardous for passenger aircraft can still be flown on freighters. These packages must bear the specific “Cargo Aircraft Only” label, allowing for larger quantities than passenger flights permit.

Sea Freight: The IMDG Code

Maritime transport follows the International Maritime Dangerous Goods (IMDG) Code.

- Flexibility: The IMDG Code generally permits much larger quantities per package and allows for a broader range of hazardous classes that might be strictly forbidden on aircraft.

- Segregation: While flexible, sea freight requires strict segregation of incompatible chemicals within a container to prevent reactions during long voyages.

Operational Reality: Capacity and Handling

The physical handling of chemicals differs vastly between an airport warehouse and a seaport container yard.

Air Freight constraints

- Aircraft Configuration: you must understand aircraft profiles. Narrow-body aircraft (single aisle) can typically only carry loose or bulk cargo in their lower deck holds. Wide-body aircraft are required for larger palletized shipments or Unit Load Devices (ULDs).

- Documentation: Air cargo requires the Notification to Captain (NOTOC), a critical document informing the pilot of the specific location and nature of any dangerous goods on board.

Sea Freight Scalability

- Volume: Sea freight excels in moving massive volumes. Chemicals can be shipped in ISO Tanks (bulk liquid containers) or as Full Container Loads (FCL) of drums and IBCs. This scalability makes it the default for industrial chemicals where cost-per-liter is the primary KPI.

- Storage: Seaports often have dedicated hazardous cargo zones designed for longer dwell times, whereas airport cargo terminals are designed for rapid throughput and may have limited storage for dangerous goods.

The Financial Breakdown: Direct vs. Indirect Costs

The price tag is often the deciding factor, but “cost” goes beyond the freight invoice.

Direct Costs: The Chargeable Weight Factor

- Sea Freight: Rates are generally calculated based on volume (CBM) or per-container flat rates. It is undeniably cheaper for heavy, dense cargo.

- Air Freight: Costs are significantly higher, often 12-16 times that of sea freight. Crucially, air freight uses a different volumetric divisor. The Chargeable Weight is the higher of the actual gross weight or the volume weight.

- Formula: Length (cm) x Width (cm) x Height (cm) ÷ 6000.

- Impact: Light, bulky packaging (often required for DG compliance) can skyrocket air freight costs due to this density calculation.

Indirect Costs: The Hidden Factors

- Inventory Carrying Cost: Sea freight’s slower transit time (30-45 days vs. 3-5 days for air) ties up capital in floating inventory. For high-value chemicals, the cost of capital can outweigh the freight savings.

- Risk Exposure: Longer transit times increase exposure to temperature excursions, piracy, and rough handling, potentially raising insurance premiums.

Case Study: High-Stakes Pharmaceutical Logistics

The pharmaceutical industry provides the clearest example of why shippers choose air freight despite the higher cost. In this sector, logistics is not just about transportation; it is about maintaining the identity, strength, quality, and purity of the drug product. Here is a specific breakdown of why air freight is essential for this sector:

Precision Temperature Management (The “Cold Chain”)

Moving pharmaceuticals isn’t like moving furniture; these are biological products that can become ineffective or dangerous if the temperature fluctuates even slightly.

- The Rulebook (IATA TCR): Logistics managers must strictly follow the IATA Temperature Control Regulations (TCR) manual. This is the industry standard for handling healthcare products based on World Health Organization (WHO) guidelines.

- Active Technology: Unlike sea freight which often relies on passive cooling, air freight allows the use of “Active Packaging Systems.” These are specialized Unit Load Devices (ULDs) equipped with mechanical heating/cooling units and thermostats.

- Benefit: They actively regulate internal temperature regardless of the outside weather on the tarmac.

- Specific Temperature Ranges: Air freight infrastructure is designed to maintain specific ranges defined by the drug’s active ingredients:

- Refrigerated: +2°C to +8°C (e.g., Vaccines).

- Controlled Room Temperature (CRT): +15°C to +25°C.

- Deep Frozen: -10°C or below.

Speed as a Safety Factor (Avoiding “Time Abuse”)

In pharma logistics, “Time Abuse” is a critical risk factor. Excessive transit time increases the probability of temperature excursions (failure) and expiration.

- Urgent Delivery: Air transport is ideal for products with extremely short shelf-lives, such as serums, live vaccines, or human donor organs.

- Clinical Trials: When launching a new drug, samples must reach laboratories worldwide simultaneously for testing. Air freight accomplishes in hours what sea freight does in weeks.

- The Cost of Failure: While air freight is expensive, the cost of losing a container of high-value drugs due to a sea freight delay—or the “social cost” of a patient not receiving a life-saving vaccine—far outweighs the shipping fee.

Decision matrix: when to choose which?

| Feature | Choose Air Freight | Choose Sea Freight |

| Shipment Weight | Small (< 100 kg – 500 kg) | Large (> 500 kg), Bulk, FCL |

| Value of Goods | High Value (Pharma, Electronics) | Low to Medium Value (Industrial) |

| Urgency | Urgent / Emergency (< 5 days) | Planned Replenishment (> 30 days) |

| Shelf Life | Short / Perishable | Long / Stable |

| Hazardous Class | Permitted on Aircraft (CAO) | Forbidden on Air / High Volume DG |

| Budget | Performance-driven budget | Cost-driven budget |

Conclusion: supply chain resilience

The choice between air and sea freight for chemicals is rarely binary. It is a strategic decision that balances Cost against Risk.

While sea freight supports the bulk of industrial chemical movements, air freight remains the “premium insurance” for high-value, high-risk supply chains. Future trends point toward a hybrid approach, leveraging Green Logistics (favoring sea for carbon reduction) and Digitalization (favoring air for visibility).

Initiatives like the e-AWB (Electronic Air Waybill) are streamlining air cargo, replacing paper contracts with digital data to improve speed and accuracy. For modern logistics managers, the ability to pivot between these modes using data-driven insights is the key to resilience.